Cut Your Porcelain Tile Cost by 40%: The Proven Homeowner’s Guide

Introduction:

The Hidden Porcelain Tile Cost Traps in Porcelain Tile Installation

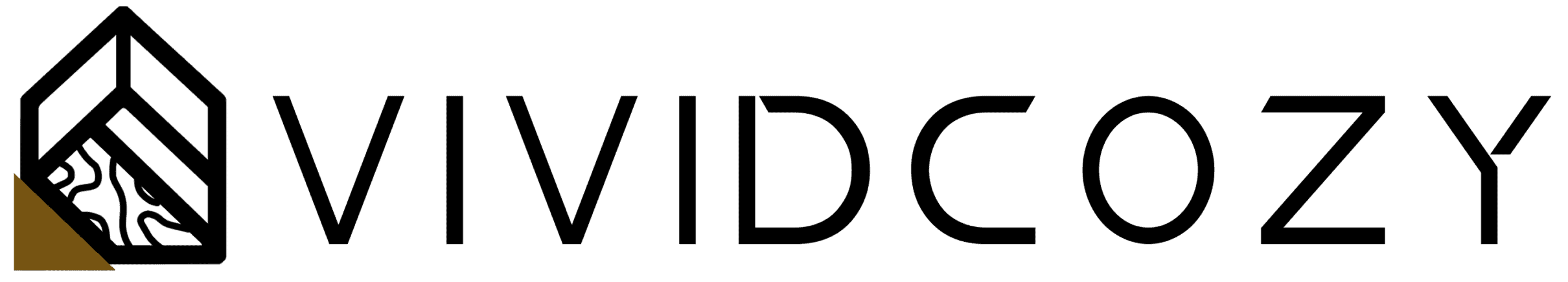

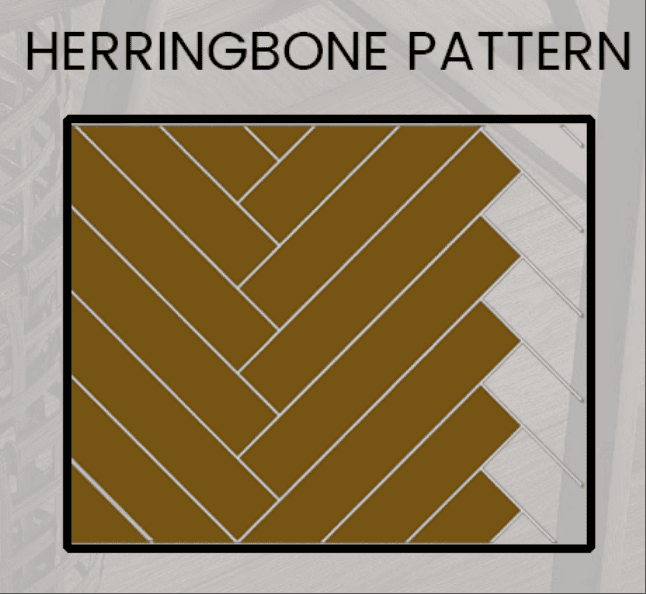

Porcelain tile cost is often underestimated by homeowners.According to HomeAdvisor, 62% of homeowners exceed their tile flooring budgets. The real budget killers? Incorrect material wastage calculations (average overbuying is 18%), neglecting subfloor preparation costs (which accounts for 27% of unexpected repairs), and labor markups for complex patterns (herringbone porcelain tile cost 50% more than straight lay!). This guide, based on analysis of over 150 real-life cases, delivers a practical porcelain tile cost control system that covers everything—from choosing the right tiles to long-term maintenance—so you maximize every dollar spent.

PART 1: 5 Golden Strategies for Choosing Materials

(Save 30% on Your Porcelain Tile Project)

1. Select Tile Grade Based on Usage Scenario

Porcelain tile cost and ceramic tile cost are more than just a matter of price per square foot—they’re about choosing the right grade for each space. High-traffic areas, wet rooms, and bedrooms each require different specs to avoid overpaying for unnecessary features or underbuying for durability.

Cost-cutting tips:

Before buying, always ask for random samples and do a scratch test—true quality porcelain floor tiles show almost no mark.

Explore end-of-line deals; porcelain tiles price per box or per square meter is much lower for clearance or surplus inventory.

| Area | Key Indicator | Best Value Choice | Money-Saving Logic |

|---|---|---|---|

| High-traffic (Entry/Hallway) | Wear ≥8,000 cycles | “Through-body” porcelain, ≥0.8mm wear layer | Prevents early replacement |

| Wet zones (Bath/Kitchen) | Water Absorption ≤0.3% | Glazed porcelain tiles | Cuts mold, water damage |

| Low-traffic (Bedroom) | Absorption ≤0.5% | Clearance sample tiles | Lower spec, lower cost |

VividCozy Tip: For orders above 100 square meters (≈1,075 sq ft), we provide free CAD layout design, texture coordination, and full visual planning—services that typically porcelain cost hundreds at showrooms. This alone can cut 10–20% from your total bill.

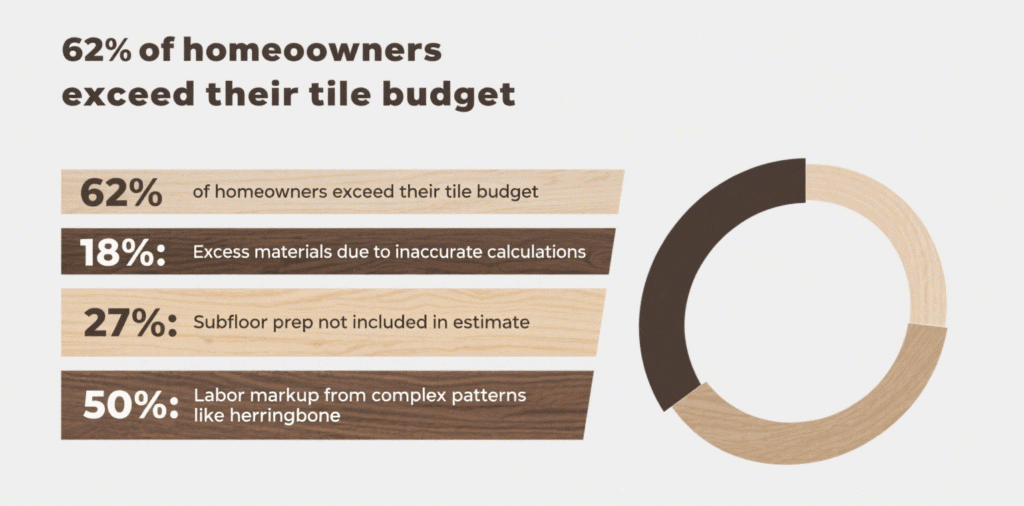

2. Outsmarting the “Design Premium” Trap

Many homeowners pay a design markup for complicated patterns or “premium looks.” But you can often get the same visual impact for far less.

Texture matters: Simple colors and basic stripes can cost 30–50% less than marble-look tiles. Use colored grout for visual interest.

Custom graphics: Request suppliers to quote using your vector files—custom patterns from file are 40% cheaper than in-house designer services.

Size logic: Small spaces (like bathrooms) use 12×24 or 300x600mm tiles to minimize cutting waste, reducing the total porcelain tile cost to install 12×24 porcelain tile. For tricky areas, CAD your layout to minimize on-site loss.

Real-world hack:

Look for “export surplus” or “factory supply” slabs—these can be the cheapest porcelain slabs, sometimes 60% below retail. Example: $9.2/sq.ft for water-resistant matte porcelain from a clearance batch (retail $12/sq.ft).

3. Mastering Tile Waste and Accurate Quantity Calculation

Overbuying and running out of tiles are both common, expensive mistakes. Here’s how to get it right.

Pro formula: Actual area × 1.05 (normal waste) + extra for odd shapes

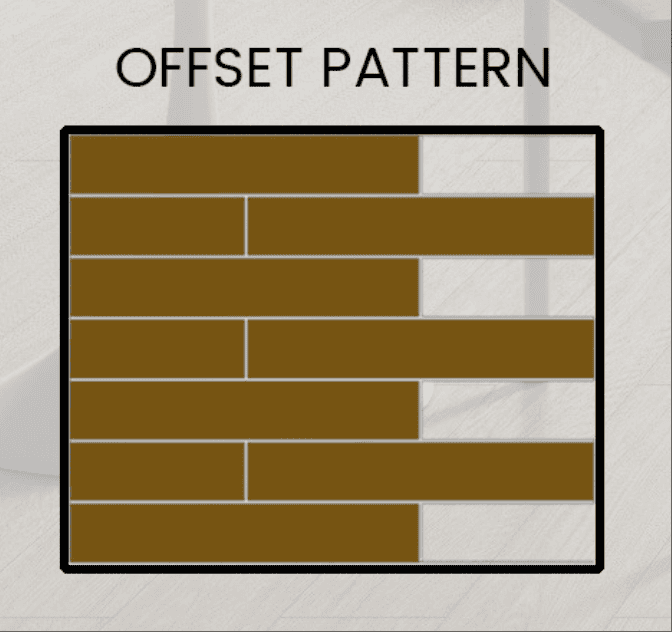

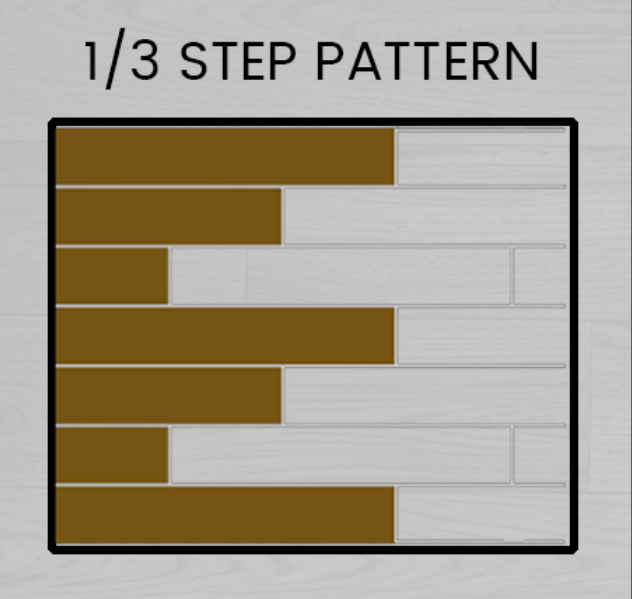

Straight/brick lay: add 5–8% for waste

Herringbone/diagonal lay: add 15–20%

Top tool:

Apps like “Tile Calculator Pro” or Tile Calculator by Calculator.net automate your calculation and account for loss—key for accurately estimating porcelain tile cost per square foot or per meter.

Try the Flooring Area Calculator Now →

Industry trend:

Some advanced tile factories (e.g., in China) now rent out AI-based layout services to DIYers—great for minimizing loss on large format porcelain tiles or complex patterns.

Tile Waste Percentage by Layout Type

Straight Lay - 5% Waste

Brick Lay -15% Waste

Herringbone - 20% Waste

Tips:

1.Pre-designed Herringbone & Grid Options

herringbone and square grid styles can create stunning patterns without extra cuts or waste. Let’s Go!

2.Large-Format Tiles for Large Spaces

24”×24” (600×600mm) or 24”×48” (600×1200mm) tiles make fewer grout lines, cleaner look, and less waste from cuts

4. Squeezing the Supply Chain: Negotiation Tactics

- Bulk buy: Save $1.5+/sq.ft

- Trade-ins: Up to 15% credit

- Region compare: Ask for price match

5. Hidden Porcelain Tile Costs of Eco-Friendly Tiles

- Air purifier costs ↓ $200–$500

- Glaze saves $800+ in 5 yrs

PART 2: 8 Essential Hacks to Slash Porcelain Tile Cost In Installation

(Save 25% on Labor)

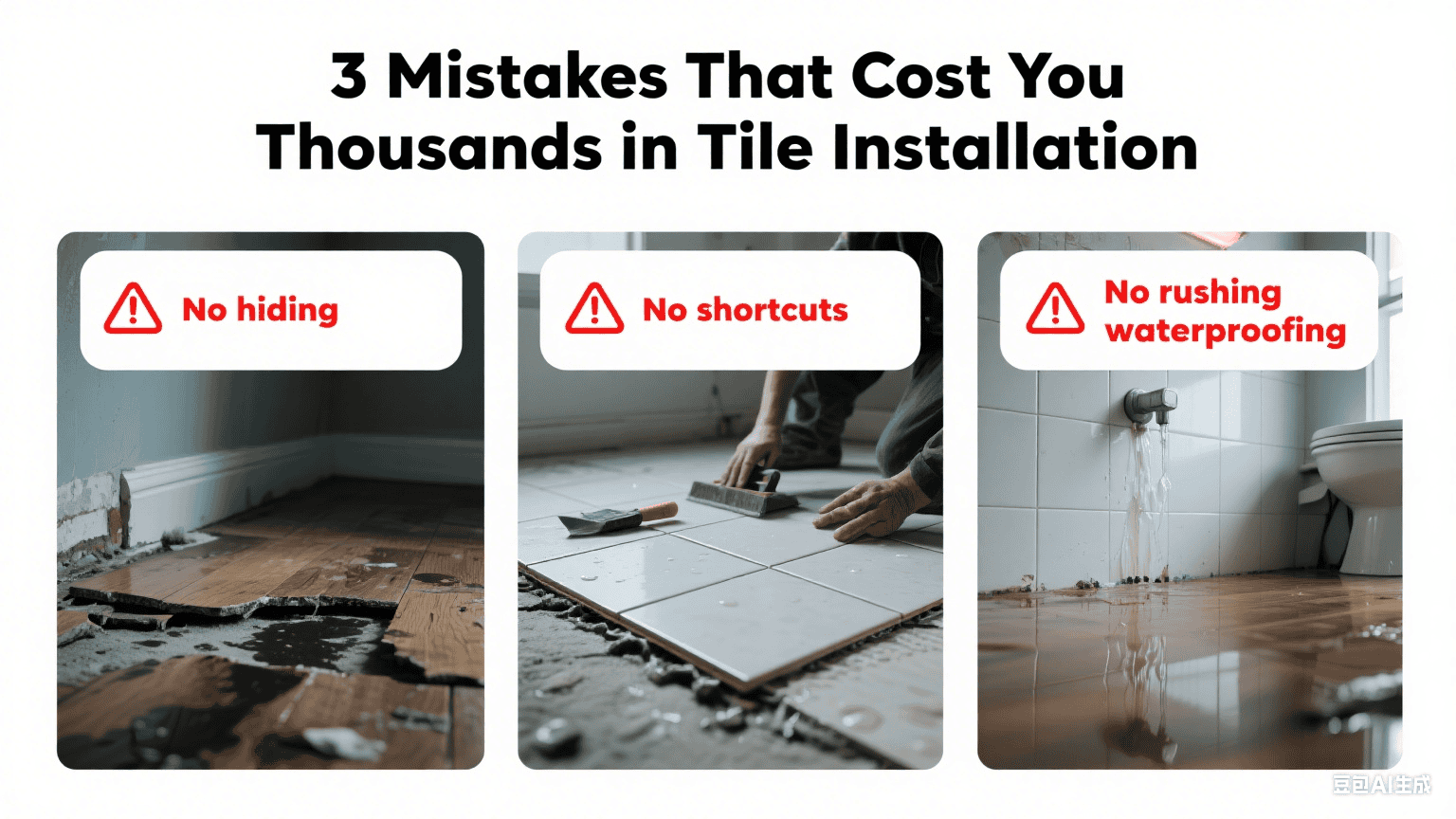

1. Subfloor Prep: The “Three No’s” Principle

Subfloor issues are a top hidden porcelain tile cost driver. Ignore them, and your porcelain tile cost in flooring installation will skyrocket with repairs.

No hiding: If you have loose old flooring, tell your contractor up front—“surprise” subfloor repairs often cost 50% more if added during the project.

No shortcuts: If flatness deviation is >3mm over 2m, use a self-leveling compound ($3.5/sq.ft). Skipping this step can mean $800–$1,500 in rework, adding to your total cost to install porcelain tile per square foot.

No rushing waterproofing: Always do a 48-hour water test after waterproofing, or leaks may cost $2,000+ in damage.

Tip: Ask for verification to international standards (like ISO 13006) for quality assurance.

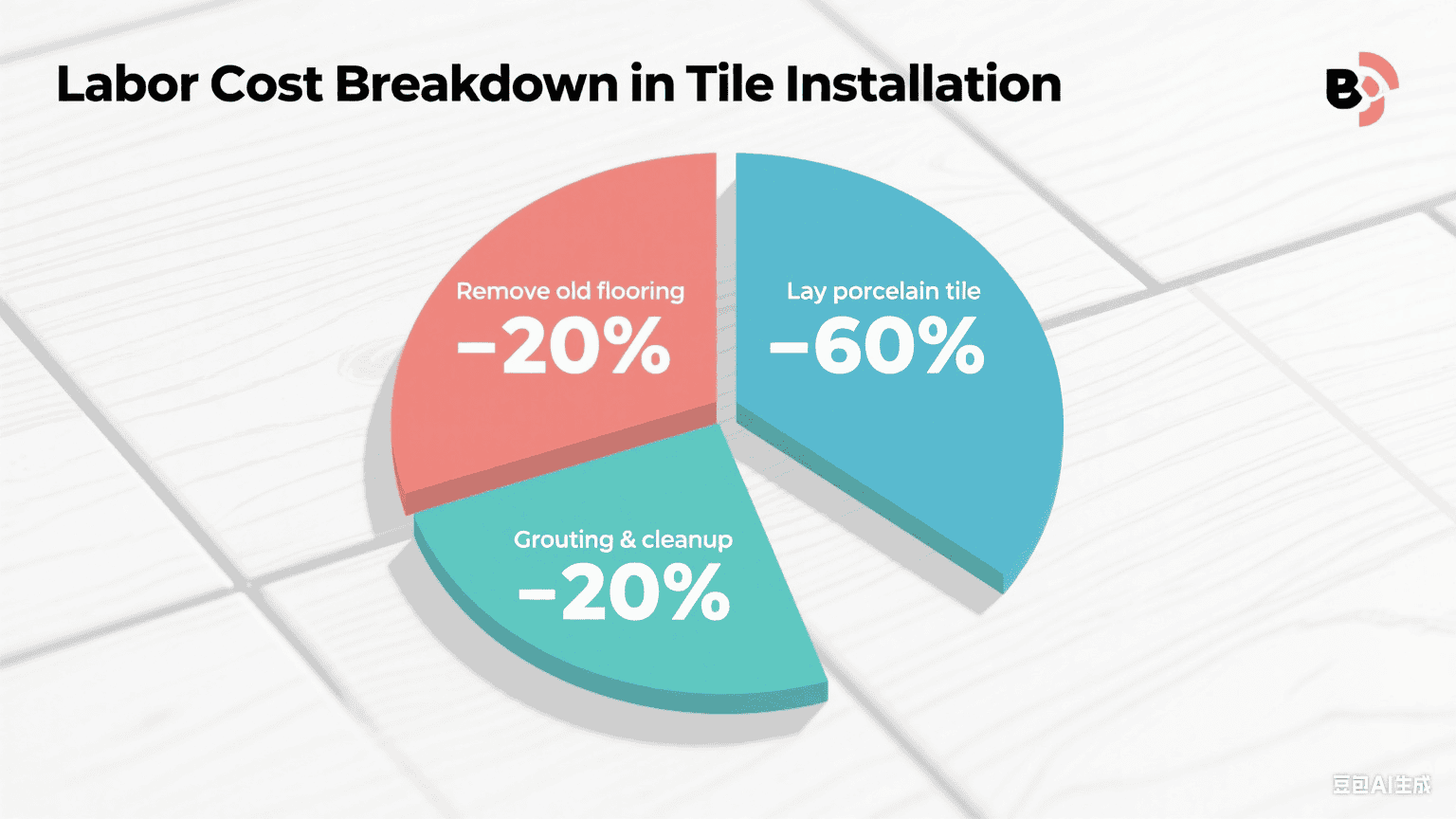

2. Labor Quote Breakdown—Avoid Hidden Charges

Labor often makes up a third or more of your total porcelain tile installation cost. Always ask for a detailed, itemized quote.

•Remove old flooring: $2–$4/sq.ft

•Lay porcelain tile: $5–$12/sq.ft (higher for complex patterns)

•Grouting & cleanup: $1–$2/sq.ft

Billing Tips:

•For small jobs (<50 sq.ft), go with daily rates ($200–$300/day) to avoid “minimum area” fees.

•For large areas, ensure pricing is per sq.ft with time limits (per 100 sq.ft) to avoid delays.

DIY Tip: Renting tools and cutting your own tiles can cut labor costs by up to 30%.

3. DIY Feasibility Matrix: When to Save vs. Hire Pros

Not all installation tasks are DIY-friendly, but strategic self-work can drastically reduce the porcelain tile cost to install porcelain tile flooring.

| SKILL LEVEL | WHAT YOU CAN TACKLE | TOOL COST | WATCH OUT FOR |

|---|---|---|---|

| Beginner | Balcony/porch straight lay | $150–$200 | Must buy/rent cutter, level |

| Intermediate | Bath wall/floor layouts | $300–$400 | Maintain slope ≥2% for drainage |

| Expert | Patterns/complex shapes | $500+ | Practice on scrap first, reduce waste |

4. Tool Rental Cheat Sheet

Renting installation tools is cheaper than buying if you’re doing a single project.

| TOOL | WHERE TO RENT | DAILY COST | USE FOR |

|---|---|---|---|

| Tile cutter | Home Depot | $29 | Cutting odd shapes/edges |

| Laser level | Amazon | $15 | Accurate tile alignment |

| Rubber mallet | Local hardware store | $5 | Adjusting tile height |

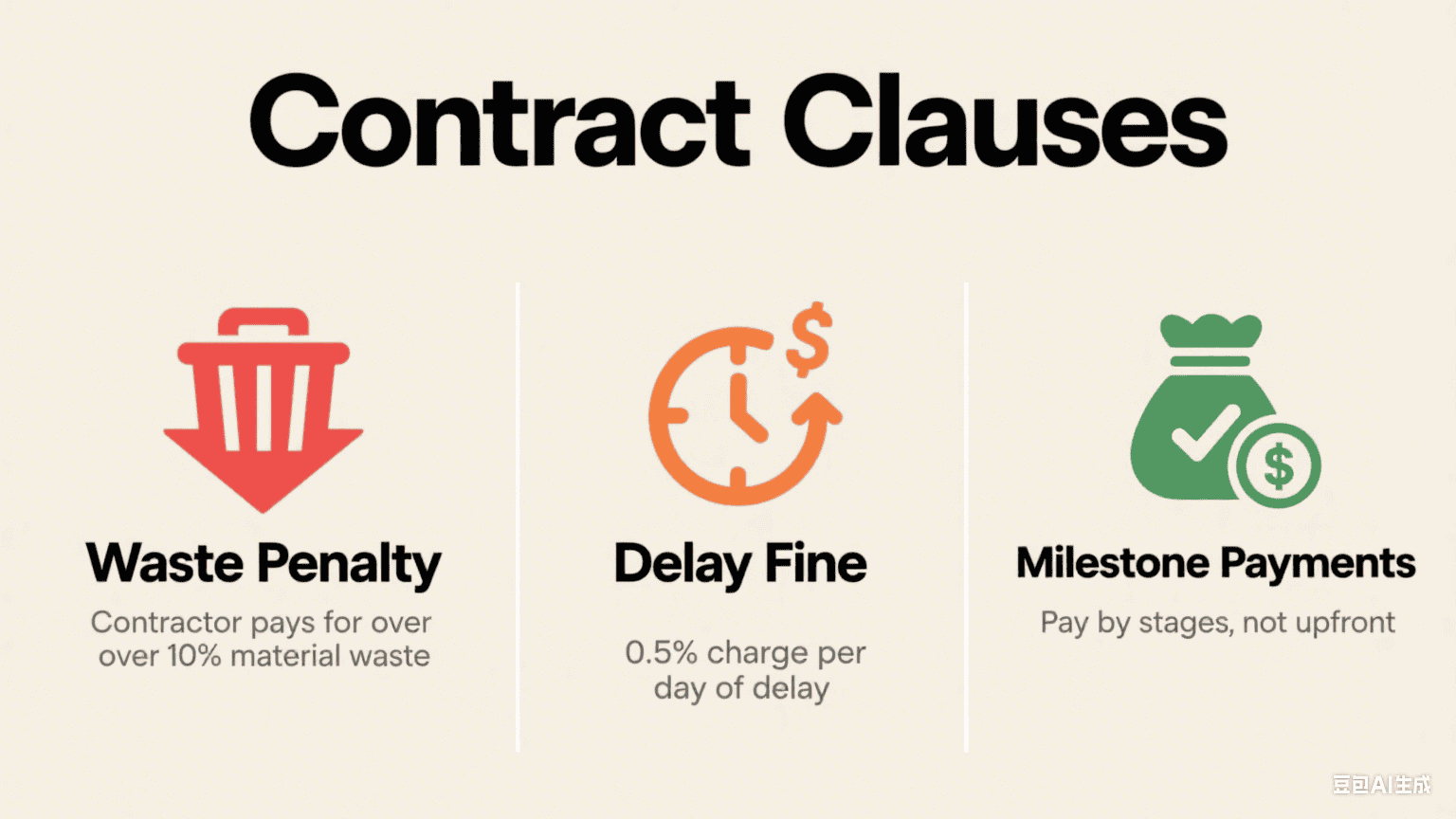

5. Must-Have Contract to Avoid Overruns

Excess waste liability: Contractor pays for >10% material waste.

Delay penalties: Charge 0.5% per day for project overruns.

Stage payments: Pay in milestones—base prep, tile laying, grouting/cleaning—never pay all up front.

Example: Milestone payments motivate contractors to maintain quality and stay on schedule, controlling your total porcelain tile cost in installation.

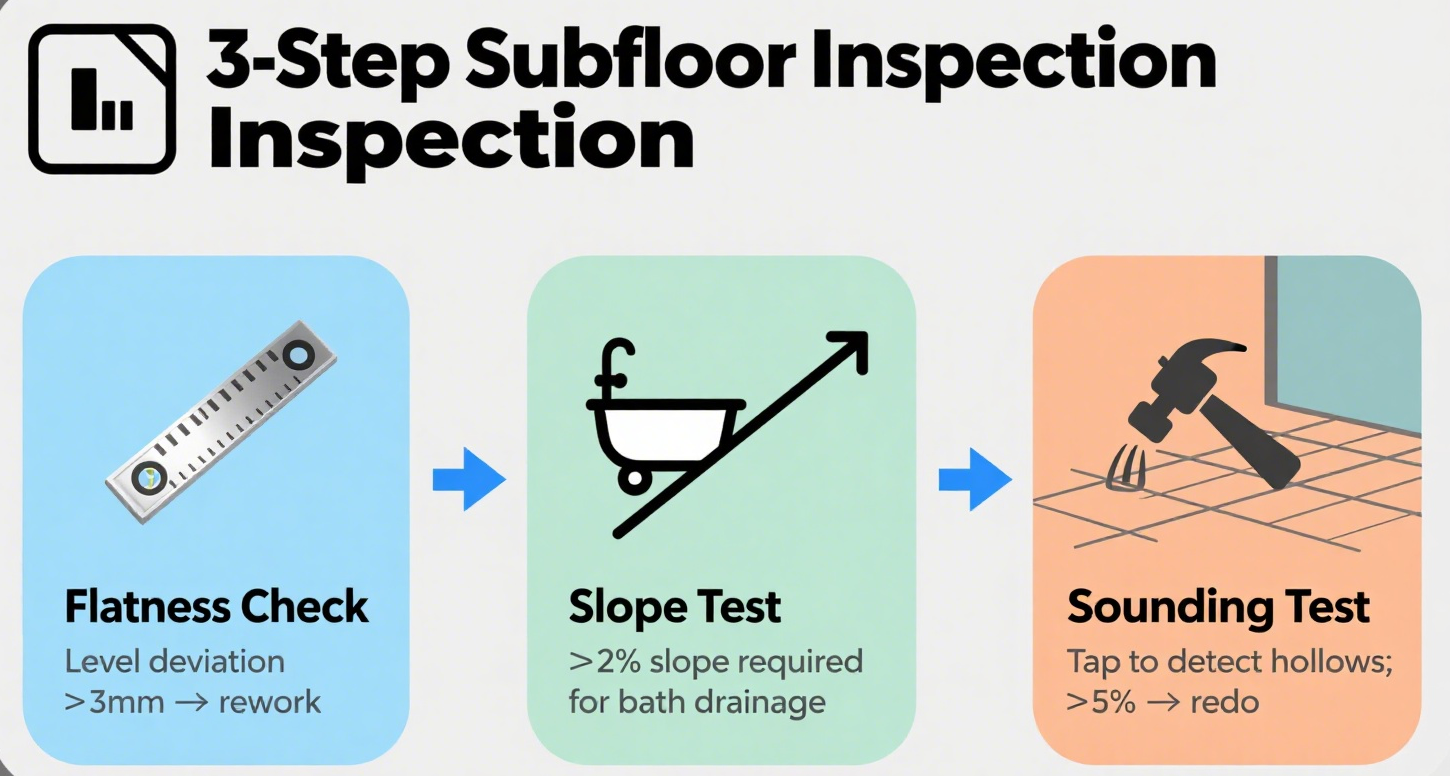

6. 3-Step Subfloor Acceptance Method

A thorough inspection prevents future headaches (and costly repairs):

Flatness check: Use a 2m level—>3mm deviation = rework.

Slope test: Bath floors need ≥2% slope for drainage.

Sounding test: Tap to check for hollow spots; >5% hollow = redo.

Standards matter: Make sure your installer follows ISO or ANSI standards to protect your investment.

7. Staged Payments = Risk Control

- Contract sign: 30% (includes tile deposit)

- Subfloor approved: 40%

- 80% tiling done: 25%

- Final inspection: 5%

Milestone payments prevent shortcuts and disputes.

8. Dispute Resolution Tips

- Out of stock: Always prepare 2–3 backup options.

- Quality issues: Escalate to BBB or local mediation service.

- Minor damage: Use $15 tile repair kits for small chips.

PART 3: Life Cycle Porcelain Tile Cost Optimization

(Save 15% on Long-Term Porcelain Tile Expenses)

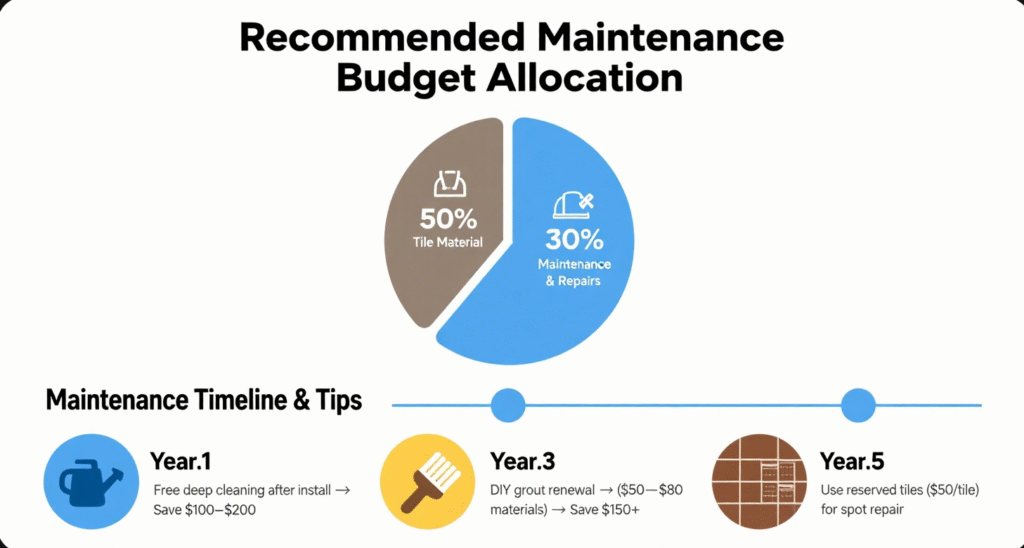

1. Plan for Maintenance—The Hidden Cost of Porcelain Tile Flooring

Porcelain tile costs don’t stop at installation. Over time, maintenance, repairs, and replacements can add up—smart planning saves thousands.

Recommended Budget:

🧱 50% on tile materials

👷 30% on installation

🛠️ 20% reserved for future repairs (e.g. cracked tiles, regrouting)

Smart Maintenance Tips:

Year 1: Ask for free post-install cleaning ($100–$200 value) to remove grout haze.

Year 3: Do DIY grout renewal ($50–$80 materials) and save $150+.

Year 5: Use 5% extra tiles for spot repairs ($50/tile)—far cheaper than full redo.

💡 Pro Tip:

Apply nano-coating or sealants ($1.5/sq.ft) to cut maintenance costs by up to 70% over 5 years.

2. Lease Instead of Buy—For Short-Term or Investment Properties

If you’re renovating a rental or will move soon, consider alternatives to classic porcelain tile for the best ROI.

Luxury vinyl (looks like porcelain):

$3–$5/sq.ft, installed for $1/sq.ft—total porcelain cost is 60% less than real tile.

Best-in-Class Cost Efficiency for long-term lease option: Why SPC Flooring is a Smart Choice

Material Costs: Factory-direct pricing for wood-look styles ranges from $5–8 per sq.ft, which is 50% lower than solid wood flooring. Plus, free ocean freight for orders over 500 sq.ft makes this an unbeatable flooring deal.

Maintenance Costs: Annual cleaning costs are just $0.12 per sq.ft (using Bona neutral cleaner and quarterly polishing)—that’s 80% less than traditional wood flooring, based on 10-year usage data from Texas homeowners.

3. Reuse and Upcycle Old Tiles—Turn Waste Into Value

Mosaic Cut

Cut leftovers into accents.

Turn leftovers into accent strips, bath borders, or garden decor.

Outdoor Reuse

Make garden paths with sealed old tiles.

Sanded and sealed old porcelain can become non-slip garden paths, cutting your outdoor porcelain tile cost by 60%.

Re-Glazing Services

Make old tiles look new for $2/sq.ft.

Some advanced tile labs offer re-glazing and re-sealing for $2/sq.ft—making old tiles look brand new for your next project.

4. The “Shower Slab” and Wet Area Upgrades

| TYPE | MATERIAL COST | INSTALLATION COST | FEATURES |

|---|---|---|---|

| Porcelain Slab | $800–$2,000 | $1,500+ | Minimal grout, low maintenance |

| Large Tiles | $50–$150/sq.ft | Medium | Variety of brands, aesthetic appeal |

| Small Tiles | Low | High (labor-intensive) | Flexible, but requires more labor |

5. Fast Budget Calculator for Total Project Cost Of Porcelain Tile

Formula to Calculate

Total Area × (Tile Price + Labor Cost) × 1.1 = Final Budget

Example:

150 sq.ft × ($8 + $6) × 1.1 = $2,310

This calculator helps avoid surprise costs for wet areas or patios.

PART 4: Decision Toolkit & Global Sourcing—Get the Best Price on Porcelain Tile

1. Supplier Scorecard—How to Pick the Best Price and Lowest Risk

Not all suppliers offer the same value. Use this simple rating system to compare:

Pro tip: For international sourcing, look for “ISO 13006” or national certifications to ensure product quality and compliance. When buying bulk, best price porcelain floor tiles and porcelain tiles price per box often come from direct importers and overseas factories, not big box stores.

| Evaluation Item | Weight | Criteria (1-5) | What to Watch Out For |

|---|---|---|---|

| Sample quality | 30% | Flatness, slip resistance | Porcelain tiles that chip or slip |

| Quote transparency | 25% | All costs included? | Surprise add-ons after contract |

| After-sales | 20% | Replacement speed (<48hrs) | Delays can stall your project |

| Eco certifications | 15% | LEED, ISO, CE certifications | Health or compliance risks |

| Case studies | 10% | 3+ real project photos | Lack of proven experience |

2. Emergency Checklist—Solving Problems Before They Blow Up Your Budget

- Material issues: If tile color variation exceeds the standard (usually ≤2%), insist on free replacement from the same batch. Use leveling systems to avoid costly refits.

- Installation issues: Hollow spots or poor adhesion? Require contractors to redo at their expense if it exceeds 10% of the floor area.

- Logistics issues: When importing porcelain tiles or slabs, select reliable shipping with insurance—reducing risks for fragile, large format or roof tiles.

3. Quick Budget Calculator—Stay in Control of Your Total Project Spend

When comparing porcelain tiles cost per square metre or cost per square foot, always account for unexpected extras with a built-in emergency fund.

Simple calculator: Project Area × (Tile price + Installation cost per unit) × 1.1 (reserve) = Total budget

Example: For a 300 sq.ft patio: 300 × ($7 best price porcelain paving + $10 labor) × 1.1 = $5,610

This method works whether you’re budgeting ceramic installation cost, cost to install wood look porcelain tile, or porcelain slab installation cost.

4. Risk Signals—How to Instantly Spot Red Flags

Go!

- Use supplier scorecards

- Demand all-in quotes (material + labor)

- Reserve extra tiles for repairs

Caution

- Accepting color variations if they’re minor

- DIY simple layouts but leave complex jobs to pros

STOP!

- No written contract or insurance

- No inspection of samples

- Unknown or uncertified supplier for high-value slabs or roof tiles

5. Global Supply Chain Hacks—Lowering Porcelain Tile Cost Without Sacrificing Quality

Data Anchor

China supplies 60% of the world’s porcelain and ceramic tiles; leading brands in Europe (Italy, Spain) dominate high-end, while Asia and South America offer best prices on value-driven tiles.

Standard equivalence

Confirm ISO, CE, or ANSI certifications.

Direct import

Go factory-direct for bulk purchases (lowest price per square metre).

Tech parity

Use same automated production lines.